Improving New Service Development

Profile

ASCM Northern Colorado (NOCO) provides exceptional educational and networking opportunities for supply chain and operations management professionals in Colorado, Kansas, Wyoming, Nebraska, and Montana. The organization is a leader in innovative education and certification programs on a variety of Lean and supply chain topics. Beyond classes, stay connected events include educational presentations, facility tours, and networking activities. Volunteers also benefit from a wide variety of leadership development opportunities which help them improve their skills in strategic thinking, public speaking, and managing organizational dynamics.

“The beauty of Lean is how the tools can be applied to any process or value stream. Before this project, I had only used Lean on the plant floor. Through the Certified Lean Master course, I learned there is often more opportunity to impact back office processes that are rarely the focus of improvement efforts.”

– Pat Ferren, Principal, Executive Partners

Challenge

The process to evaluate and launch new services, such as certification programs, targeted courses on best practices, and different formats for stay connected events was undocumented and highly variable. As a organization of volunteers, there is limited time for analysis and no desire for a complicated process that would slow down the need to respond to new customer needs. In addition, new people come in with big ideas, but no structure for articulating the idea and providing a business case for adding a new service. The lack of a clearly defined process caused some new services to languish in the development funnel while others would flow through without sufficient analysis.

The NOCO board of directors recognized the need to define an effective and efficient process for assessing new services along with a structure for gaining approval to commit limited volunteer resources to helping launch and maintain a new service. The NOCO board challenged Pat Ferren to leverage the project based Certified Lean Master course to improve the value stream for new service development. Pat was charged with finding a solution that leveraged best practices while keeping the effort required to a level appropriate for a volunteer based organization.

Engagement

Pat leveraged the Certified Lean Master course to structure his project. As a lengthy and low volume process, Pat and his team could not simply “walk the process” to create a current state value stream map. As an alternative, Pat and his team created the current state map by assessing the four most recent new service launches that NOCO had completed over the prior two years. As expected, the current state map identified large variations in time to market and in the actual activities conducted for moving new ideas through the new service development funnel.

Before creating a future state map, Pat recognized some fundamental elements required for bringing a new service to market where missing from the NOCO process and from the mind set of the team. Pat researched best practices and provided the team with required reading assignments concerning the Stage Gate Process.

Armed with a current state map that highlighted the significant waste everyone wanted to eliminate and tooled up with knowledge on best practices, the team was ready to proceed. Pat then led a Kaizen Blitz event to create a future state map. Then was followed by a gap analysis and project plan for closing the gap.

The team presented the plan to the executive steering committee and received approval to proceed.

Results for ASCM Northern Colorado

The new service development process for NOCO is efficient and effective. Standardized work has been incorporated via three new documents (Idea Log, Product Concept Summary, and Scoping Checklist) and an emphasized use of a Business Case document that NOCO uses for justification of improvement projects. The new service development value stream is well documented for helping new volunteers, requires a small, but appropriate time investment by the NOCO board to approve new services, and significantly reduces the time to market by 60%. In addition, the use of a stage gate process requiring a business case for justification will mean the new services will be launched with full support from the NOCO board and alignment of volunteer resources required for success.

“Pat did a great job helping us “walk the talk” as we craft a Lean organization. It is imperative that we improve our value streams using the same tools we teach to our customers.”

– Tom Villiers, CEO, ASCM Northern Colorado

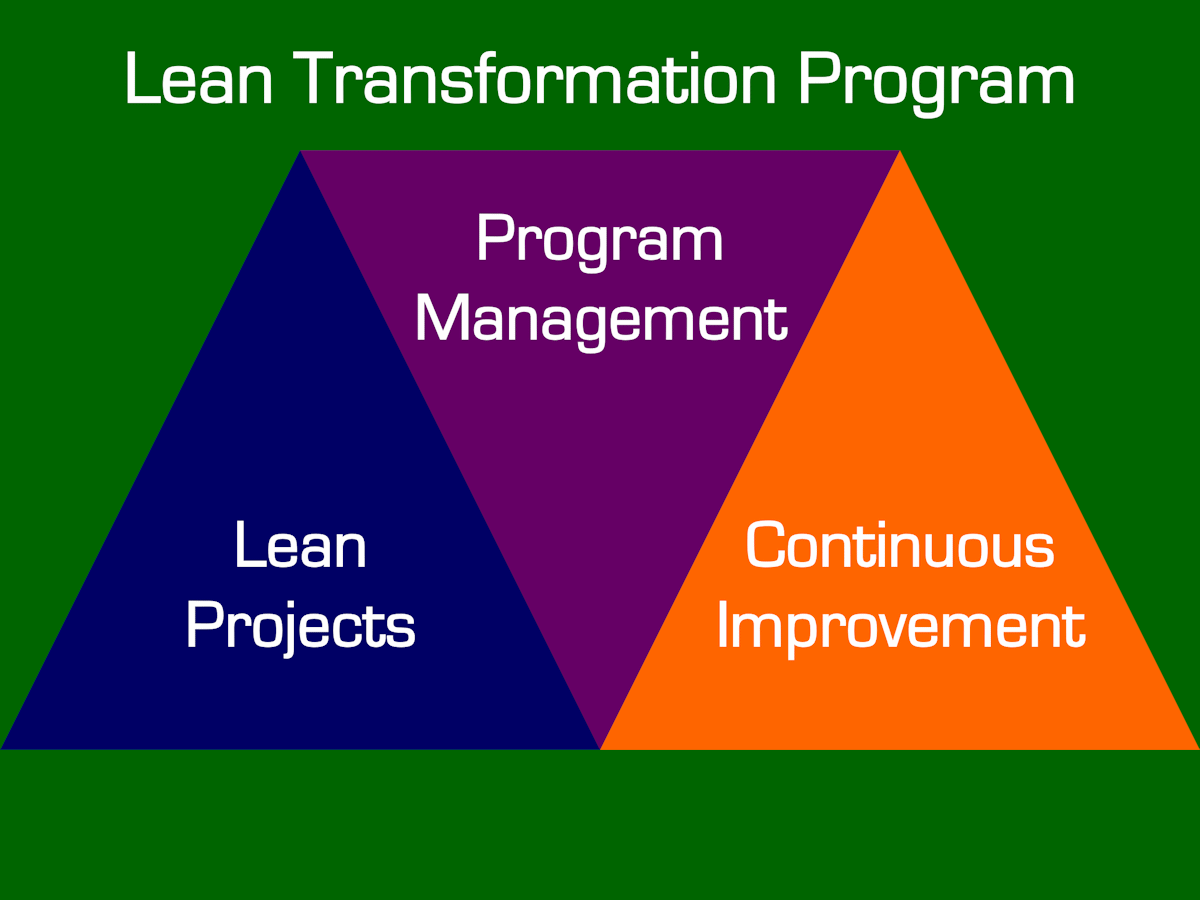

Lean Transformation Program

A Lean Transformation program is one of the best investments any organization can make. The return on investment (ROI) is better than many other strategic initiatives. Eliminating waste will improve customer satisfaction, increase revenue (or impact), and reduce costs.

The best Lean programs will contain three critical components:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

Learn more about the program, from Transformance Advisors, at: Lean Transformation Program.

What is Lean?

The Credential Registry

Workforce Center Success

What is Lean Transformation?

Loyola University Chicago Success

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors