By Mike Loughrin, CEO for Transformance Advisors

Lean is Systematic

On a daily basis, I continue to be impressed by the people I meet who have a deep understanding of Lean as the systematic elimination of waste. These experts understand Lean tools are systematic and you must apply them step by step. So, 5S or 6S, which is it?

We can debate which tool to use and when to use it. But, there should be no debate on using each tool correctly.

We have all seen the wake of destruction caused by charlatans who practice chaotic cost cutting. While, these impostors will have Lean on their resume, they lack the basic understanding of Lean as systematic and are probably incapable of grasping Lean as a cultural transformation.

But enough of my soapbox proclamations, let’s look at a debate with The 5S System.

The 5S System is Systematic

Value stream mapping, changeover reduction, and the 5S system are just a sample of the Lean tools which are systematic. You benefit the most when you apply them in their own unique proper sequence.

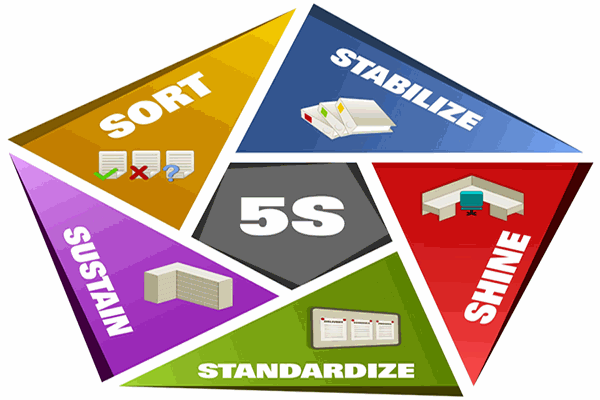

The 5S system is famous for being effective in the simplicity of following five systematic steps.

You must sort, stabilize, shine, standardize, and sustain in the prescribed sequence. It does not work if you standardize before you sort.

Is Safety Another S?

A challenge to the 5S system has arisen in how some people do not fully appreciate how systematic approaches are the key to a successful Lean Transformation.

Some of these people claim “safety” should be added as the sixth S. This claim fails to recognize how safety is not a systematic step.

While very important, safety cannot be listed before, between, or after any of the proper steps in the 5S system.

Now, I am willing to listen to a good argument and I have heard quite a few cases pleading for the sixth S of safety. These arguments all rely upon three undisputed facts:

- Safety starts with an S

- Safety is important

- Safety feels like it fits with sort, stabilize, shine, standardize, and sustain

The above are three good points, but the argument for the sixth S of safety ignores three other facts which are undisputed by Lean experts:

- Lean is the systematic elimination of waste

- The 5S system is a systematic program from the Lean tool box

- There are thousands of words which start with an S and fit with sort, stabilize, shine, standardize, and sustain.

5S 6S Conclusion

In my assessment, the 5S system should remain a systematic program which requires the sequential application of each step.

In the spirit of continuous improvement, I have increased my awareness of safety as important throughout all the steps in the 5S system.

I will not limit safety to something which is done as a specific step. It is important all the time.

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. Mike has helped organizations such as Levi Strauss, Warner Home Video, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

Practical 5S

All Wrong About 5S!

Apply 5S To Your Life

Recognizing the Need for Lean

What is Changeover Reduction?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors