By Mike Loughrin, CEO for Transformance Advisors

Lean is Number 1

It seems like everyone is working to make their organization Lean! And in fact, many organizations are improving performance and changing their culture through effective Lean Transformation programs.

In contrast, other organizations are simply using a few common techniques from the Lean tool box. Sadly, they are just scratching the surface and are far from reaping the big rewards available to those taking a comprehensive approach.

There are also many organizations where solid Lean programs exist in one functional area, but senior executives have not seen the possibilities, or they lack the courage, to include all functional areas.

Common Elements

To understand the gap between the leaders achieving big gains and the laggards taking small steps, let’s explore the common elements of effective Lean Transformation programs.

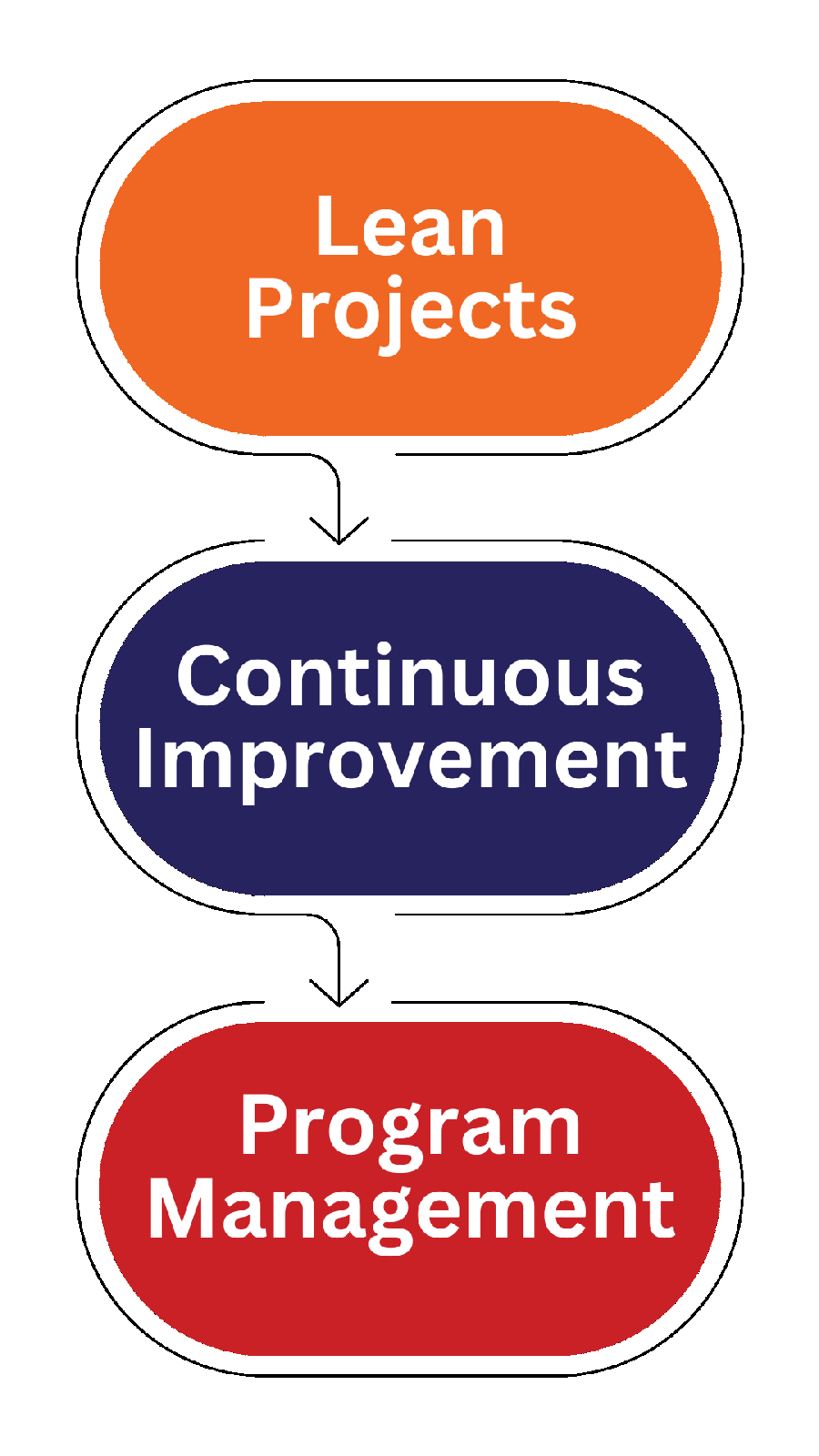

Our research and experience indicates the following 3 components are key indicators of success:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

While each of the above components provide great value, it is the synergy between them which makes for a successful Lean Transformation. Your ability to craft a sustainable organization is far better when you have all of the pieces of the puzzle than with any alternative approach.

Leaders vs. Laggards

Using these 3 components of success, let’s examine the differences between the leaders and the laggards:

1. Lean Projects

Leaders

The leaders take a very systematic approach when applying the five principles of Lean and leveraging key concepts such as the types of waste. Lean Projects using proven methodologies such as value stream mapping, changeover reduction, problem solving, and the 5S System produce better and stable processes. Each type of Lean project has it’s unique and systematic steps which are the key to success. The leaders use the key to unlock significant improvement.

Laggards

The laggards find one or two techniques from the Lean tool box which seem easy and they overuse these techniques in an attempt to cut costs in a chaotic manner. Not following the systematic approach built into each Lean tool will often result in an unsatisfactory outcome. It is often a lack of project management expertise which holds the laggards back. One executive reported they had given up on Lean Projects because of failure after failure to achieve success.

2. Continuous Improvement

Leaders

The leaders understand how no project will create perfection and constant change means a process needs to keep changing to meet the new realities. The Lean Projects create a stable process which needs to be followed by Continuous Improvement. Empowered employees will get to the root cause of issues and use techniques, such as kaizen blitz events and “Plan Do Check Act”, to create a culture of Continuous Improvement.

Laggards

The laggards believe continuous improvement is a simple process. Even worse, some laggards think Lean is only a simple continuous improvement program. Both are wrong. One Lean charlatan proudly announced on LinkedIn how Lean is just telling people to start fixing things. That’s like handing a hammer to an auto mechanic and telling them to fix your broken refrigerator. The laggards don’t know what they don’t know.

3. Program Management

Leaders

The leaders have a solid foundation supporting the Lean projects and continuous improvement activities. They have someone, or a small team, with the time and ability to ensure program management activities, such as establishing priorities, managing the budget, and communicating progress, are being taken care of. The leaders will also take time to “step back to reflect” on the effectiveness of their Lean Transformation program. It’s only common sense to apply continuous improvement to one of the best investments you can make.

Laggards

The laggards will not have the time or energy for program management. At best, someone is known as the “Lean person” who also has another full-time job doing something more important. There is no budget for training or projects. Laggards tend to learn by skimming articles and viewing a few webinars. Even worse, they fall for the Lean Charlatans who proclaim Lean is easy and all you need is to just do something and hope it works. The laggards don’t have a Lean program and don’t think about their lack of progress.

Summary

Lean is #1 because it has a rich history of success. Those who focus on the systematic elimination of waste supported by a comprehensive Lean Transformation program are the leaders. Those who chase cost cutting in a chaotic manner, without the desire for a cultural transformation, are the laggards.

The return on investment between the leaders and the laggards is great. However, there is good news for the laggards. They can get on the road to success by leveraging the 3 critical components of Lean Transformation programs.

We do not need leaders and laggards! Through a comprehensive Lean Transformation program, all members of the Lean community can be winners.

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. Mike has helped organizations such as Levi Strauss, Warner Home Video, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

What is Lean?

Real Lean vs. Faux Lean

What is Lean Transformation?

Recognizing the Need for Lean

What is Continuous Improvement?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors