Creating Competitive Advantage

“The team from Transformance Advisors has taken us to whole new level with our Lean Transformation!”

– Thom Mandl, CEO, Mount Sopris Instruments

Profile: 60 Years Producing Geophysical Instrumentation Systems

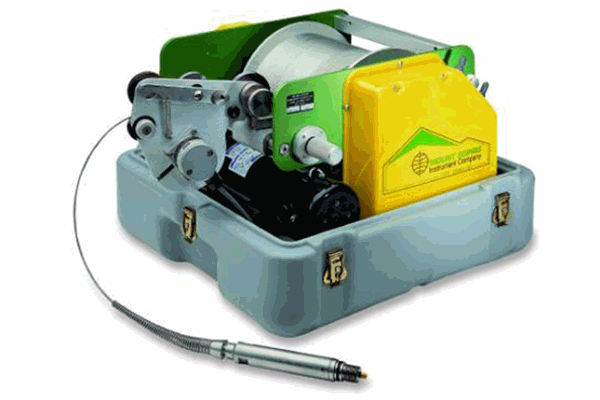

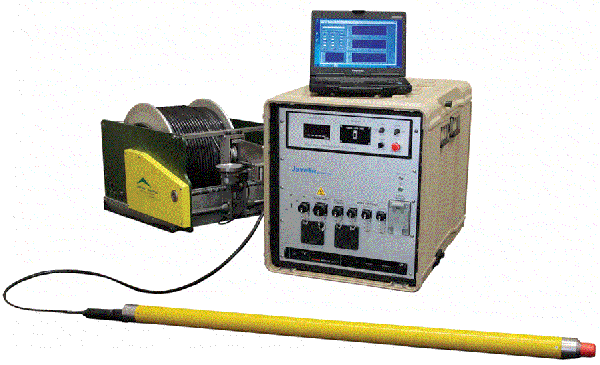

Mount Sopris Instruments is a leading manufacturer of geophysical slimhole borehole logging systems for groundwater, mining, research, geotechnical, and other applications – featuring a complete range of stackable wireline probes, rugged logging winches, versatile data loggers, and best-in-class WellCAD software.

For over 60 years, Mount Sopris has delivered innovative solutions to drillers, miners, engineers, and researchers in over 120 countries around the world. With an extensive product range and industry-leading customer support, Mount Sopris is dedicated to the success of their customers.

Mount Sopris was founded in Boulder, Colorado in 1951 at a time when locating uranium for weapon and reactor use was of national interest. The company’s first product was a portable scintillation counter. Early on, Mount Sopris joined forces with another Colorado company, one that made respirators for use by polio victims. Learn more at: history of Mount Sopris Instruments.

“The program from Transformance Advisors has given us a fast start with getting Lean implemented into our organization.”

– Curtis Baker, Plant Operations Manager, Mount Sopris Instruments

The Challenge: Market Conditions Require Increased Operational Efficiency

Given that Mount Sopris supplies instruments to the mining and natural resource markets, sales can be substantially impacted by fluctuations in natural resource prices. The recent down cycle in commodity prices has resulted in decreased demand from the company’s core customers, while at the same time, increasing competition from other geophysical instrument system manufacturers.

As a result of these challenges, Mount Sopris, under the leadership of CEO Thom Mandl, undertook a comprehensive review of its competitive position. The leadership team determined that decreasing customer order fulfillment cycle time offered significant value to customers and would create a long term competitive advantage.

Understanding that it needed to move quickly with this opportunity, Mount Sopris interviewed a number of consultants and decided to partner with Transformance Advisors for guidance, leadership, program development, and delivery. Project cost was supported by the Rocky Mountain Trade Adjustment Assistance Center (RMTAAC) through TAA for Firms, a U.S. Department of Commerce program that assists manufacturers impacted by increased import competition and other grants arranged through Manufacturer’s Edge.

The Engagement: Lean Culture Begins to Take Root, Step By Step

First Steps: Certified Lean Master

Two members of the Mount Sopris team became Certified Lean Masters through Transformance Advisors. This represented the first steps in creating a Lean Transformation and helped them understand the enormous potential of Lean.

Once the team developed an understanding of the “Lean Tool Box”, they went to work on initial projects with the guidance of the team from Transformance Advisors.

Next Steps: Putting the Knowledge to Work

The highest priority issues addressed in the first phase included:

- Establishing a regular and formal process for Forecasting, Sales & Operations Planning, and Master Scheduling to identify opportunities to shorten order fulfillment cycle time

- Developing a new Sales Order validation and release process that completes a checklist of validation prior to making a Ship Date Commitment

- Establishing effective inventory control and transaction processing capability for all items

- Implementing a process to manage work orders using kanban and backflushing that is segmented for Make to Stock vs. Make to Order

- Established a planning tool for managing supplier kanbans to support shorter procurement lead times and effective stocking of raw materials

Additional Knowledge: Scheduling, Sourcing, and Lean

Three key employees completed the CPIM (Certified in Production & Inventory Management) program, provided through APICS Northern Colorado, and used the knowledge to drive process improvements in planning and scheduling.

Ryan Miller, from Your Local Connection, provided training and support involving strategic sourcing and supplier relationship management.

Manufacturer’s Edge provided basic Lean training for all employees that was critical for engaging everyone in the projects and developing a culture of continuous improvement.

The Results: Impressive Progress & Measurable Improvements

On time delivery has improved quickly as customer orders are now booked as “systems” rather than “pieces”.

Inventory turns have increased substantially along with a reduction in the dollar value of inventory.

Supplier on-time delivery performance has increased through improved coordination with component suppliers.

Customer order to ship days has been substantially reduced – the key objective for creating a competitive advantage.

Accounts receivable have also been reduced.

The Mount Sopris leadership feels progress, thus far, has improved its ability to quote aggressive delivery dates and compete in the challenging geophysical instrument market.

The company is well on its way to becoming a true Lean Enterprise.

Lean Transformation Program

A Lean Transformation program is one of the best investments any organization can make. The return on investment (ROI) is better than many other strategic initiatives. Eliminating waste will improve customer satisfaction, increase revenue (or impact), and reduce costs.

The best Lean programs will contain three critical components:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

Learn more about the program, from Transformance Advisors, at: Lean Transformation Program.

General Air Success

Micro Motion Success

Cartridge King Success

What is High Flexibility Scheduling?

What is Supply Chain Management?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors