By Mike Loughrin, CEO for Transformance Advisors

Achieving Strategic Sourcing

In my prior article, we explored: What is Strategic Sourcing? and developed a comprehensive and robust definition:

“Strategic sourcing is the systematic process to secure critical goods and services in a manner which is aligned with the strategic objectives of the organization. It will leverage long term relationships with suppliers and achieve the best total cost of ownership.”

It’s now time to explore what needs to happen for achieving strategic sourcing.

Strategic Sourcing Should Be Systematic!

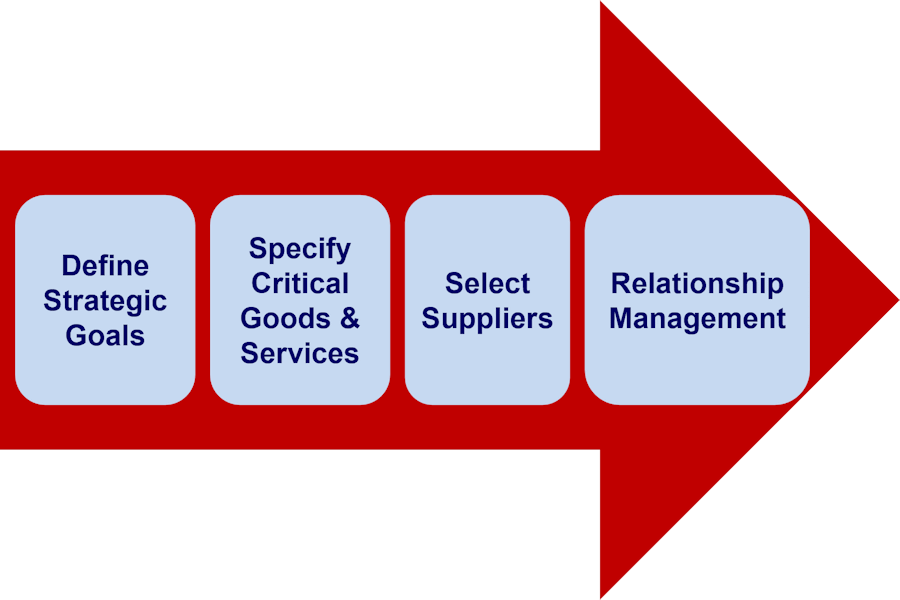

The article on Strategic Sourcing also identified a systematic and fact-based approach having four steps:

- Define Strategic Goals: What are the strategic organizational goals which must to supported? Where is alignment needed in terms of your core strategy, network strategy, strategic initiatives, social responsibility commitments, and other strategic decisions?

- Specify Critical Goods and Services: What are the items making up a large percentage of spending? What are the other items requiring special care? Then, item by item, what are the strategic goals you need to align with when you evaluate and select suppliers?

- Select Suppliers: Using your specifications for each critical good and service, find and establish relationships with suppliers. See article on Successful Supplier Selection.

- Relationship Management: Maintain and improve your relationship with each supplier of critical goods and services.

Let’s Explore Putting Strategy into Strategic Sourcing

Given our new definition and systematic approach, let’s explore how to get the “strategic” aspect correct.

Define Strategic Goals

This first step in the strategic sourcing process is called Define Strategic Goals

This effort requires understanding various strategic decisions which need to be part of your supplier selection process for each critical good and service.

These strategic decisions include:

- Core Strategy

- Network Strategy

- Strategic Initiatives

- Social Responsibility

Let’s look closer at each one.

1. Core Strategy

Your core strategy plays a extremely important role. As a quick review, there are three basic strategies an organization can choose to compete with. They are cost leadership, differentiation, and market focus. You must identify your core strategy at the very beginning. Later, you will assess how important it is for a supplier to be aligned with this core strategy.

Suppliers, of course, have the same three options (or the ever popular “stuck in the middle” disaster when leaders won’t lead). What if your supplier has a different strategy? For example, you choose differentiation by focusing on leading edge products and a supplier is focused on cost leadership. The supplier may be investing in cost reductions, but not investing in the new technology required for keeping your products at the cutting edge of innovation.

Later in the process, you will determine if a supplier needs to align with your core strategy.

I am not saying they must be aligned. But, I am saying you will need to assess this issue and come up with an answer. Will you want suppliers for a specific good or service to be aligned, or will you feel it is not important for a supplier to share your core strategy?

2. Network Strategy

In terms of strategic sourcing, do you want suppliers who are local, regional, or scattered across the globe?

Companies like Toyota are global, but they choose to operate regional plants, with regional suppliers, in the countries where they sell their cars. One of Toyota’s goals is to have suppliers positioned within a 2 to 3 hour drive from their assembly plants.

The key point is, before you start searching for suppliers for each critical good and service, you identify the preferred location for targeting your search.

Another factor is dealing with relativity in terms of the size of the suppliers you seek to partner with. If your suppliers are smaller, you may have more control. But, they may not be able to keep up with your demand and growth rate. If your suppliers are larger than you, they may well have more than adequate resources to support you. But, you may get lost in the shuffle as they choose to serve their larger customers first.

You must determine the desired size of potential suppliers for each critical good and service. In the end, you may not have much choice. But, at least, you will have a better understanding of the risks associated with dealing with a supplier who is much smaller or larger than your organization.

One last assessment involves selecting suppliers who may be your competition. Or, even more common, suppliers who sell to your competitors.

The question for each critical good and service is acknowledging the consideration of buying from a competitor. For items, such as common raw materials, this may not be an issue. Other items, such as marketing programs, may involve very sensitive information which must not fall into the hands of your competition.

3. Strategic Initiatives

Your sourcing strategy should also be in alignment with those 3 to 5 strategic initiatives identified as the top priorities for your organization.

The assessment needs to determine whether sourcing for each critical good or service:

- Has no impact on any strategic initiative

- Must be aligned with one or more initiative

- Will be key to the success of one or more initiative

The chart on the right is just a sampling of possible strategic initiatives.

It’s fairly easy to see how sourcing decisions could have a significant impact on the success of many initiatives.

Gaining a deep understanding of each strategic initiative and aligning the sourcing strategy is one of the big gaps which can be eliminated for many organizations.

| Sample Strategic Initiatives |

|---|

| Lean Transformation |

| Enter New Markets |

| Launch New Product Line |

| Implement ERP System |

| Expand Capacity |

| Focus on Core Competencies |

| Develop New Sales Channel |

| Mergers and Acquisitions |

4. Social Responsibility

A growing concern regarding sourcing strategy, is Social Responsibility. This includes factors such as labor conditions, resource consumption, environmental pollution, and animal welfare.

Problems at suppliers with poor social responsibility practices have had an extremely negative impact on the image of many organizations.

This assessment needs to determine whether sourcing for each critical good or service must be aligned with your social responsibility goals. Do you want your suppliers to report to you or to an independent reporting organization?

Alternatively, you may not be concerned about certain social responsibility values of a supplier. Rolling the dice is certainly an option for a small and decreasing number of companies.

In deciding which option to choose, a company should recognize consumers are apt to hold them responsible for lapses at any and all levels in the supply chain. The times are a changing.

For example, one of the big and growing social responsibility issues is reducing your carbon footprint.

Governments, non-government agencies, corporations, and individuals are all taking action to reduce the amount of carbon emissions for which they are responsible.

An independent not-for-profit organization called the Carbon Disclosure Project (CDP) maintains a database of 2,500 organizations in some 60 countries around the world. Each of them measures and discloses their greenhouse gas emissions. Many leading companies have already deselected suppliers who have failed to manage their carbon emissions.

Social Responsibility – Quick Case Study

During a panel discussion at a recent sustainability conference, one panelist shared the challenges with social responsibility and strategic sourcing.

This large international organization has made a commitment to reducing their carbon footprint. They have made numerous public statements and the CEO reports on their progress to the board of directors and at the annual shareholders meeting. It is a big deal and they are committed.

They are making great progress and have invested in a dedicated sustainability team to support all business units. This team has found carbon footprint reduction efforts almost always provide a direct reduction in operating costs. And in other cases, the publicity of their efforts has led to increased revenue from like-minded organizations who appreciate what they are doing.

But, change can be hard!

In one example of resistance to change, a “sourcing professional” switched from a supplier of electricity which used wind power to another supplier who relied on coal-fired power plants. The excuse was “I got a lower price; that’s what I’m supposed to do.”

The result of this switch was a large increase in the carbon footprint for this business unit based in Europe. The VP of Sustainability was discouraged, but sought to dig into the cost dynamics of this decision. Many other changes had found how reducing carbon emissions tends to lower costs and create those true win-win scenarios. It was time to see if this situation was different.

Digging deeper showed a small price reduction was available by signing a long term contract with the coal-fired power plant. This electric utility is losing business and scrambling to find customers.

But, as most us know, price is not the same as total landed cost or the more comprehensive total cost of ownership. Turns out, switching to coal-fired electricity meant the company would lose tax credits for the wind power they used from the former supplier and then pay a carbon tax for the new supplier. The deal was a loser and should never have been made.

The self-proclaimed sourcing professional had not looked at total cost of ownership and had only considered the purchase price.

Old bad habits are hard to break!

It’s way past time to be making decisions only on purchase price. It’s been said how “using purchase price variance as a performance measurement is one the most foolish things you can do!”

Summary

It’s time to put strategy into strategic sourcing.

The first step is to define the strategic goals for your organization, in terms of core strategy, network strategy, strategic initiatives, and social responsibility.

This will be fairly easy if your leadership team does an effective job with strategy development and execution.

For others, the sourcing professional may raise a number of questions about decisions which have not been made or have not been communicated

Regardless of the effort required, you cannot do strategic sourcing without including strategy in the process.

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. Mike has helped organizations such as Levi Strauss, Warner Home Video, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

What is Line of Sight?

Critical Goods and Services

What is Strategic Sourcing?

Successful Supplier Selection

What is Supply Chain Management?

Subscribe to our newsletter

References

Why Companies Should Consider Strategic Sourcing by Michigan State University.

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors