By Mike Loughrin, CEO for Transformance Advisors

Collaboration Model

The Collaborative Planning Forecasting and Replenishment (CPFR) model from the Voluntary Interindustry Commerce Standards Association (VICS) identifies key collaboration responsibilities between retailers and manufacturers. CPFR is an industry standard targeted towards improvement in the flow of products and information throughout supply chains in the general merchandise retail industry.

The goal is to coordinate plans and reduce the variance between demand and supply. Another way to think about this is reducing the impact of the bullwhip effect.

“Supply chain success cannot be attained without the alignment of goals, communication, collaboration, and process integration between trading partners.”

– Patrick Looby, Retail Industry Executive

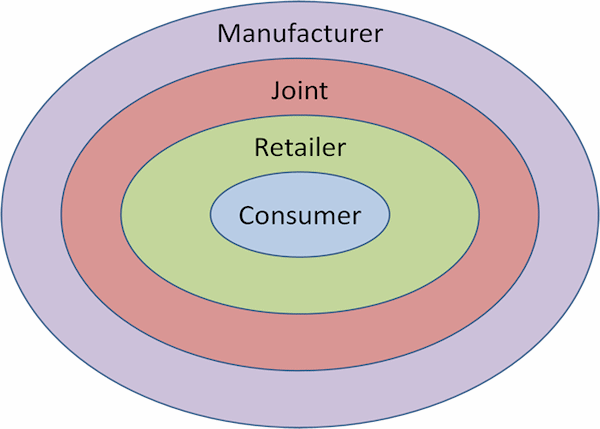

Four Concentric Rings

The CPFR model contains a series of four concentric rings.

- The “Consumer” is placed in the middle and is focal point of the entire model.

- The “Retailer” is placed in the next ring and is responsible for selling products to the Consumer.

- The “Manufacturer” is placed in the outermost ring and is responsible for securing supplies and making the products sold by the Retailer.

- The ring between the manufacturer and the retailer is reserved for the “Joint” processes which make up the heart of the collaboration processes that power the CPFR model.

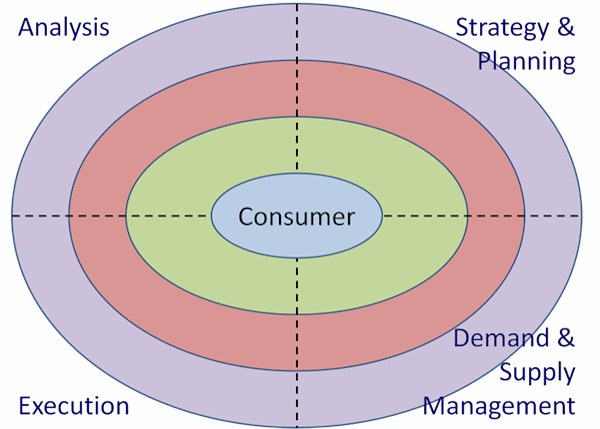

Four Process Categories

The three outer rings, which exclude the consumer, are divided into four categories:

- Strategy and Planning

- Demand and Supply Management

- Execution

- Analysis

These four categories are used for grouping the standard business processes that are defined as part of the CPFR model. For each ring, there are two standard business processes.

In a stroke of genius, the model does not identify any standard business processes for the consumer. It’s comforting to know that the model does not require us consumers to follow any standard operating procedures!

Manufacturer Collaboration Responsibilities

1. Strategy and Planning

- Account Planning

- Market Planning

2. Demand and Supply Management

- Market Data Analysis

- Demand Planning

3. Execution

- Supply Planning

- Logistics

4. Analysis

- Execution Monitoring

- Customer Scorecard

Joint Collaboration Responsibilities

1. Strategy and Planning

- Collaboration Arrangement

- Joint Business Plan

2. Demand and Supply Management

- Sales Forecasting

- Order Planning

3. Execution

- Order Generation

- Order Fulfillment

4. Analysis

- Execution Management

- Performance Assessment

Retailer Collaboration Responsibilities

1. Strategy and Planning

- Vendor Management

- Category Management

2. Demand and Supply Management

- Point of Sale Forecasting

- Replenishment Planning

3. Execution

- Buying and Re-buying

- Logistics

4. Analysis

- Store Execution

- Supplier Scorecard

Focus on Retailer Responsibilities

The remaining sections of this article will focus on the eight standard processes which are identified as retailer responsibilities.

Vendor Management

The retailer is responsible for determining which suppliers they will buy from. These selection and management activities should be driven with a focus on the strategic objectives of the retailer.

A retailer with outlets across the globe will seek suppliers with global capabilities. A small retailer may favor local producers.

A growing trend for grocery stores and restaurants of all sizes is to source food from local producers. This trend is being driven by consumers seeking local foods with higher nutritional value that are grown without the large amounts of fertilizers and pesticides used by many large corporate farms.

Category Management

The retailer is responsible for determining which product categories they will offer to consumers and how broad of an assortment they will carry for each category. This process includes an analysis of how many different brands and which types and sizes of packaging to offer. In addition, category management also includes an assessment of how much shelf space to provide for each item. For many retailers, the shelf space assessment could lead to the option of no shelf space for those items that will only be offered through their online store.

The ultimate objective of category management is to design a product offering whereby the retailer can maximize the profitability of the entire category. Some items may be sold at low or negative margins because of the need to offer a complete selection without seeming to be overpriced. In rare occasions, an entire category may be unprofitable, but it brings consumers in the door and helps with selling other profitable categories.

Point of Sale Forecasting

For this responsibility, the retailer should predict what they think they will sell. The point of sale (POS) is when the customer checks out at the cash register.

The POS forecast is not an estimate of what the retailer will buy, what the manufacturer will ship, or what the manufacturer will make. Many other factors, including inventory levels, transportation costs, and equipment capabilities will determine how the POS forecast impacts other echelons in the supply chain. The emphasis for this retailer responsibility is helping determine what the true consumer demand will be.

One important aspect for POS forecasting is getting to the right level of detail. Generally, it is unrealistic to seek a detailed daily forecast for every item at every store going out many months into the future. This is a fool’s errand and should be avoided.

Replenishment Planning

In terms of replenishment, the retailer is responsible for setting up and managing the routine replenishment of store shelves. This could include the use of distribution centers that supply the retail stores.

A large number organizations have adopted the use of vendor managed inventory (VMI) programs. These programs may shift some of the replenishment planning activities to the manufacturer.

As with POS forecasting, the objective of replenishment is not to create a detail plan for every item going out many months into the future. The goal is to have a plan for the routine replenishment of store shelves as products are sold to consumers. This is a planning process and execution should be driven by actual consumer demand.

Buying and Re-buying

The retailer is responsible for the actual buying and re-buying of products from the manufacturer. However, this is another area that has been simplified through the use of VMI inventory programs.

In most VMI programs, the retailer’s buying process may include issuing a blanket purchase order and the re-buying process may be turned over to the manufacturer. In these cases, the rules of engagement would authorize the manufacturer to replenish the retailer and keep them between an agreed upon minimum and maximum level of inventory.

Logistics

The retailer is responsible for many types of logistics activities that take place after the manufacturer ships the product.

These activities can include:

- Receiving at the retailer’s distribution center.

- Storage, movement, and inventory record accuracy while at the distribution center.

- Picking, packing, and shipping to the retail stores.

- Transportation from the distribution center to the retail stores.

- Receiving at the retail store.

- Moving from the receiving location to the store shelves.

- Inventory record accuracy at the retail store.

- Reverse logistics in handling consumer returns.

- Reverse logistics in handling shipments back to the manufacturer.

Store Execution

In the “analysis” category, store execution refers to the retailers responsibilities for assessing performance at each store. Some important areas include:

- Getting new products through receiving and out in the store as required. Many new products have specific dates when they need to be available. They are not supposed to be available one day too soon, but should be all ready before the store opens on the designated launch date. In additions, some new products come with large promotional displays.

- Keeping all designated shelves stocked with inventory. It can be a large challenge to keep 5 or more locations all stocked at all times. Recent reports from major news organizations have explored how major retailers are having significant issues getting products from the back storage room to the store shelf. It seems that a 3,000 mile supply chain is breaking at the last 50 feet!

- Rotating stock and pulling out-of-date items. Many food products have an expiration date and need to be pulled on or before that date. Selling these products could lead to lawsuits. But, just leaving them on the shelves could lead to zero sales as consumers pass them by. Many non-food products also face similar issues in terms of being past the selling season. For example, a retailer should not have snow shovels taking up shelf space in the summer.

Supplier Scorecard

The retailer should establish the critical performance measurements that they will use to evaluate the manufacturer. Some common measures include ontime delivery, product quality, and data integrity.

For those manufacturers that are part of a vendor managed inventory program, the scorecard will include the effectiveness in keeping inventory between the minimum and maximum levels that have been agreed to.

The supplier scorecard should be shared with the manufacturer who should determine and eliminate the root cause of poor performance for any areas not meeting expectations. The supplier scorecard and process improvements should be a standard agenda item for any quarterly or annual business reviews held between the retailer and manufacturer.

Summary

The CPFR model is a great industry standard for facilitating collaboration in the general merchandise retail industry. The model identifies 24 standard business processes that are assigned to 4 categories. There are 8 processes for manufacturers, 8 for retailers, and an additional 8 that are joint responsibilities.

This article explored the processes that are the responsibility of retailers.

Future articles will examine the processes that are the responsibility of manufacturers and those that are joint responsibilities.

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. Mike has helped organizations such as Levi Strauss, Warner Home Video, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

Supplier Scorecards

Quality Disaster at Pet Store

Retail Supply Chain Challenges

Bullwhip Effect: Still Snapping…

Challenges of Creating Alignment

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors