By Mike Loughrin, CEO for Transformance Advisors

An Integrated Approach

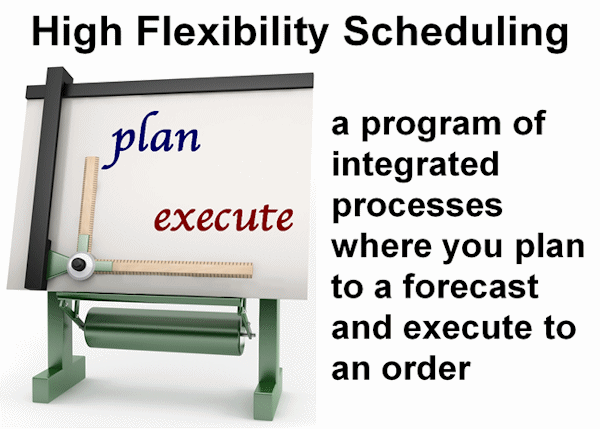

The essence of High Flexibility Scheduling, or HFS, is: “plan to a forecast and execute to an order”.

HFS is a key component of crafting a Lean organization. It provides the capability to leverage your Lean Transformation as a competitive advantage.

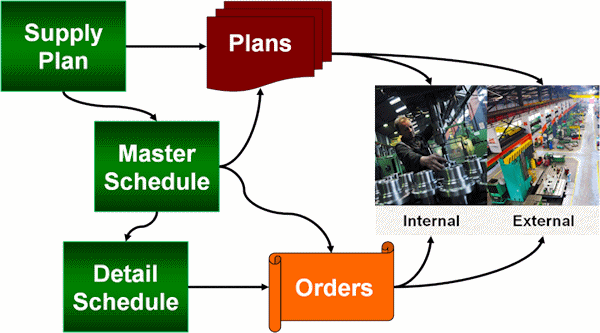

HFS is a program of integrated processes for:

- Supply Planning

- Master Scheduling

- Detail Scheduling

Let’s look closer at the three critical elements:

Supply Planning for HFS

Key points:

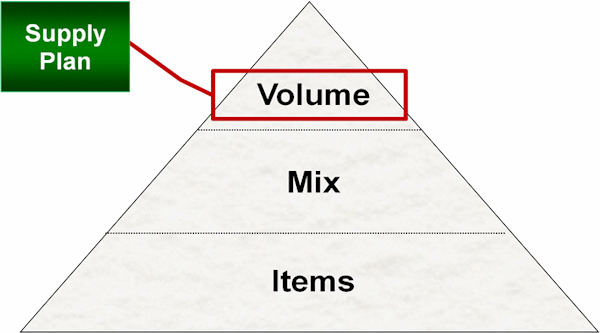

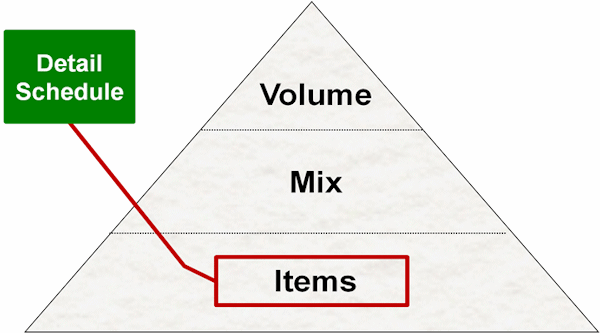

The Supply Plan is a high level plan which is focused on the volume.

It should be developed as part of the Sales & Operations Planning (S&OP) process.

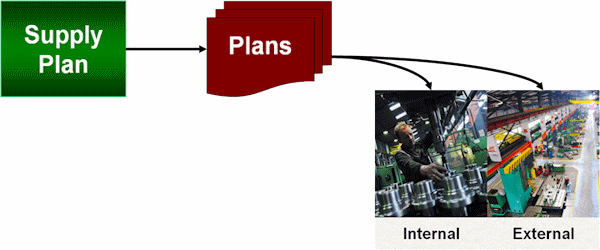

It is a plan provided to internal operations and external suppliers to help position the right resources.

Supply Planning Outputs

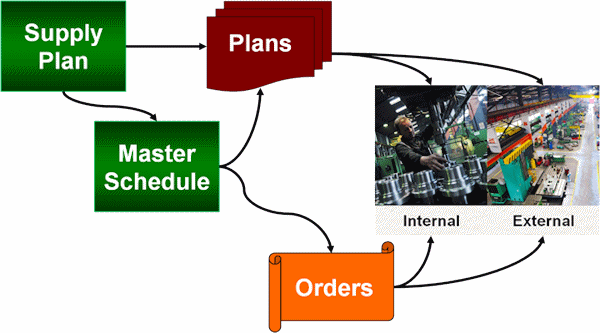

The first step in HFS, supply planning provides requirements to both internal operations and external suppliers so they may prepare in terms of capacity and materials.

They are to use this plan to position resources. This means they are not yet authorized to produce specific finished goods.

As a high level plan focused on aggregate capacity and material requirements, the Supply Plan concentrates on the volume of demand and supply.

For a Lean organization, the Supply Plan will often be created for each value stream and be the same level of aggregation used for S&OP.

Master Scheduling for HFS

Key points:

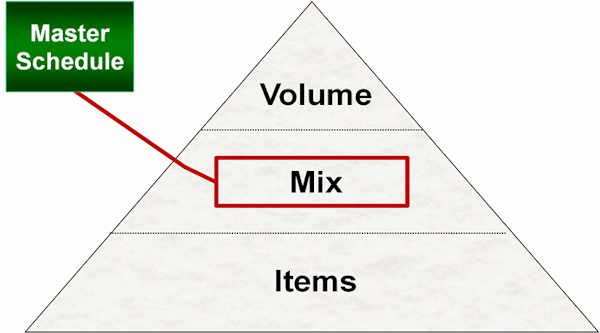

The Master Schedule is at a slightly lower level of detail than the Supply Plan and is focused on the mix.

It must be monitored and maintained so it always reflects what you intend to do.

Depending on lead times and product configuration, it is a plan which may be used to begin building or purchasing common components and raw materials.

Master Scheduling Outputs

The second step in HFS, master scheduling provides requirements to both internal operations and external suppliers so they may prepare in terms of capacity and materials. In addition, it may also create orders which drive the procurement or production of long-lead time items.

As a mid level plan focused on capacity and material requirements, the Master Schedule concentrates on the mix of demand and supply.

For a Lean organization, the Master Schedule will establish the takt time for each value stream.

Detail Scheduling for HFS

Key points:

The Detail Schedule is at the item level.

It is focused on specific customer orders or replenishment requirements.

This schedule drives the production and purchases of specific items.

Detail Scheduling Outputs

As the third step in HFS, detailed scheduling creates the orders which drive the production and purchase of specific items.

Typically, work orders are provided to internal operations and purchase orders are provided to external suppliers.

For a Lean organization, the Detail Schedule will be driven by visual controls and kanban replenishment techniques.

Summary of High Flexibility Scheduling

HFS is a program of integrated processes designed for use by Lean organizations.

Three major differences between traditional scheduling and HFS are:

- The Supply Plan is created by value stream as part of the Sales & Operations Planning process

- The Master Schedule is created at a model, or generic item, and sets the takt time for each value stream

- The Detail Schedule supports firm requirements which are communicated using visual controls and kanban replenishment techniques

Mike Loughrin is the CEO and Founder of Transformance Advisors. He also teaches for Louisiana State University Shreveport and is on the board of directors for the Association for Supply Chain Management Northern Colorado.

Mike brings exceptional experience in industry, consulting services, and education. Mike has helped organizations such as Levi Strauss, Warner Home Video, Lexmark, and Sweetheart Cup.

Keeping a commitment to a balanced life, Mike loves downhill skiing, bicycle rides, and hiking in the mountains. See one of his trails of the month at: Little Switzerland.

HFS: Insights From a Warrior

Bullwhip Effect: Still Snapping

What is The Fresh Connection?

Challenges of Creating Alignment

What is Supply Chain Management?

Subscribe to our newsletter

References

What is Supply Chain Management? by Robert Handfield, Ph.D.

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors