Value Stream Improvement Success

Profile

General Air Service is the largest independent gas and welding distributor in the state of Colorado. Established in 1969, the employee-owned company delivers compressed gases, equipment, and services to four major business segments: Industrial, Medical, Specialty, and Beverage. General Air has eight retail store locations and a fill plant in Commerce City.

They deliver the best products the industry has to offer. Using advanced systems and technologies, they are able to offer their customers a wide array of specialty services, including the expertise required to increase efficiency and lower costs.

“General Air is committed to delivering an extraordinary customer experience and healthy financial returns to its employee-owners. Due to the recent growth and cost competitiveness of the carbon dioxide market, we were eager to implement Lean in our CO2 value stream to eliminate waste, improve cycle times, and reduce operating costs. We have been very pleased with the results to date and are preparing to launch new teams to address other key value streams in our business.”

– Mark Gregory, VP of Operations

Challenge

Carbon Dioxide (CO2) is used for medical, industrial, and beverage applications. The margins are slim and forces the need for low cost production. At the same time, demand for CO2 is growing rapidly due to recent legislative changes legalizing marijuana in the state.

The CO2 fill process at General Air had never been formally analyzed and improved. The rising demand created the situation where operators struggled to meet customer demand within the target of 24 hours. This was resulting in overtime, unbillable deliveries, backorders, and dissatisfied customers.

The leadership team at General Air challenged Thom Mandl to pull together a group of employees to leverage a systematic Lean approach to analyze the CO2 value stream to find and implement improvements.

“Creating flow in the CO2 fill process was especially challenging due to the physical constraints of the property and building layout. Moreover, the variability in daily demand for a particular cylinder size underscored the importance of leveraging pull and improving employee visibility within the process.”

– Thom Mandl

Engagement

Thom Mandl enrolled in a Certified Lean Master course that was offered by Transformance Advisors in collaboration with APICS Northern Colorado. Thom, armed with the teachings from the course, formed a cross-functional team at the fill plant to address the CO2 value stream. This value stream was defined as starting with the receipt of empty cylinders from the route trucks and ending when full cylinders were loaded on the route trucks destined for customer facilities.

After education on Lean principles and problem solving tools, the team created a current state value stream map and grabbed a number of quick wins along the way. With further training in creating flow and leveraging pull, the team then created a future state value stream map and gap analysis between the current state and the future state. They identified improvements required to reduce cycle time, improve flow, eliminate defects, improve customer satisfaction, and ultimately impact financial performance. The majority of the improvements were no-cost and implemented within a few weeks. Approximately $5,000 was invested in new equipment to address process constraints and improve flexibility.

The Results:

Since the project is still underway, the final results have yet to be realized. However, the team anticipates the following from the improvements that have been or will soon be implemented:

- Overall cycle time – 25% reduction

- In-process inventory – 25% reduction

- Production and driver overtime – 75% reduction

- Backorders and unbillable deliveries – 75% reduction

- Cylinder carrying costs – 25% reduction

- Lean Transformation program – started with a big success

- Customer and operator experience – dramatically improved!

“The team at General Air was highly engaged and motivated. It was a great pleasure for me to lead them through this process. I was very encouraged with the results that we were able to achieve in a very short period of time. I am confident that the executive leadership clearly saw the benefits of Lean and is committed to making it a part of their culture.”

– Thom Mandl, Business Advisor and Certified Lean Master

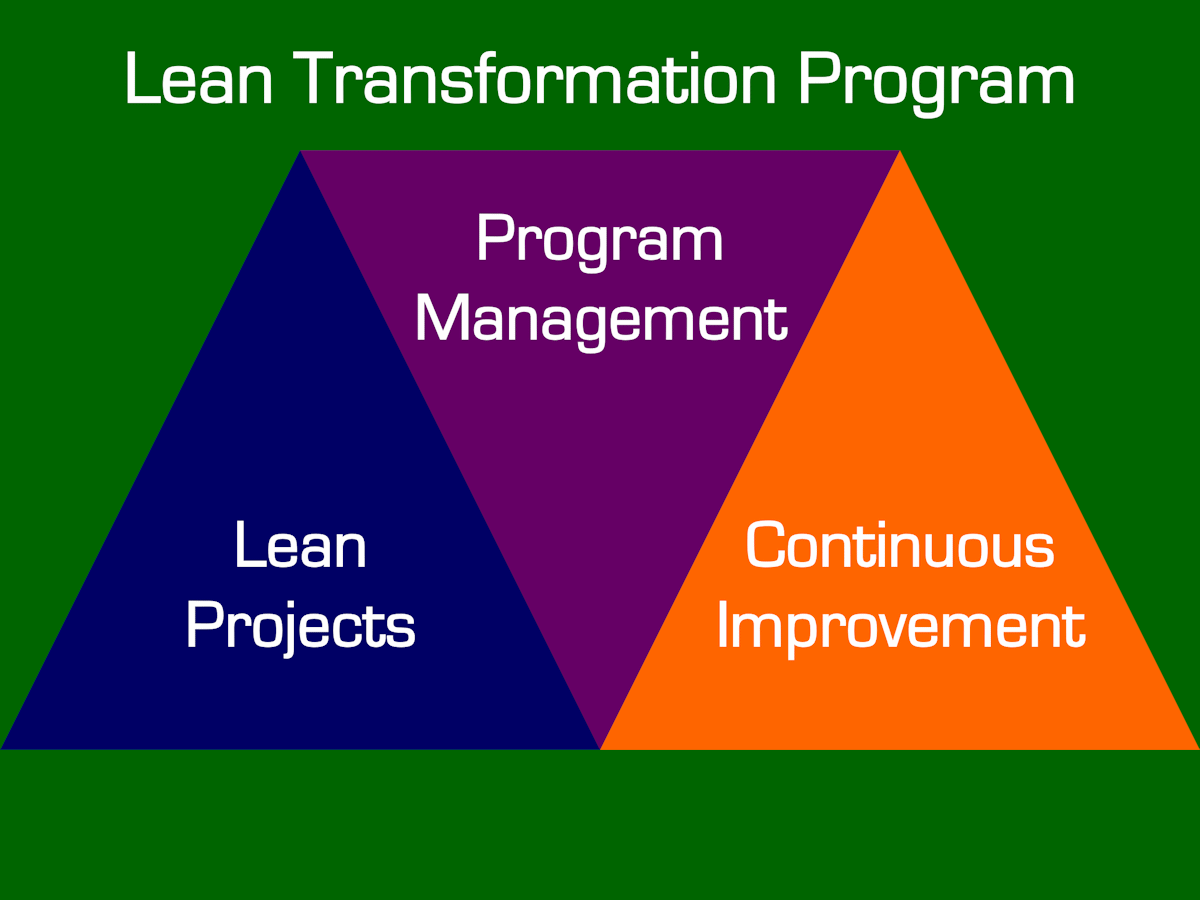

Lean Transformation Program

A Lean Transformation program is one of the best investments any organization can make. The return on investment (ROI) is better than many other strategic initiatives. Eliminating waste will improve customer satisfaction, increase revenue (or impact), and reduce costs.

The best Lean programs will contain three critical components:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

Learn more about the program, from Transformance Advisors, at: Lean Transformation Program.

Mount Sopris Success

Rubadue Wire Success

What is Lean Transformation?

Recognizing the Need for Lean

What is Changeover Reduction?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors