Improving Logistics

Profile

Talley is on a mission to provide the best service in the industry; to provide customers with the best products at the best possible price; to honor suppliers, customers, and their policies; to build every relationship for the long term; to never compromise integrity, and to respect the opportunities provided on a daily basis.

Headquartered in Southern California, with six additional operations in the United States, Talley provides same day service to much of the United States and also ships worldwide.

“As a result of the improvement methodologies taught to us by Mike Loughrin, our team has developed skills allowing them to become more proactive with suppliers, customers, internal employees, and management. This has produced a dramatic improvement in operational efficiency and cost control.”

– George R. Hulbert, CFO

Challenge

A new program to co-locate with a strategic supplier, growth in business volume, and the move to new facilities all contributed to overload the key supply chain processes required for order fulfillment. The warehousing and production assembly processes were not operating efficiently and were utilizing an excessive amount of overtime.

In addition, progress toward ISO 9001 certification was stalled and discussions had begun concerning postponement of an upcoming certification audit.

The entire team was frustrated. Talley challenged Mike Loughrin with guiding the team on how to improve the key processes in a manner which would leverage concepts in Lean logistics to accelerate cycle time and lay the foundation for continuous improvement.

Engagement

Mike provided educational sessions on Lean concepts such as value stream mapping, performance measurements, and cycle time reduction. Kaizen blitz teams were identified in areas such as Receiving, Shipping, Production Assembly, and Planning. These teams utilized the Lean concepts to design and implement improved business processes. Another key area for improvement was the organizational structure for order fulfillment where the processes and reporting relationships were not well defined.

Mike assessed the organizational structure, provided insight into appropriate best practices, and recommended improvements to strengthen the focus on meeting customer expectations.

Results

Talley’s new order fulfillment processes operate 50% faster and overtime has been reduced by 75% – all without any increase in headcount. The ISO 9001 audit was completed as originally targeted and an unconditional certification was earned. The key supply chain processes are now led by a senior executive responsible for order fulfillment.

Most importantly, the Talley team has learned the Lean methodology to improve processes and is utilizing performance measurements to enable continuous improvement.

The journey to world class performance has begun.

“The team at Talley Communications was great to work with. They were eager to learn how to follow the systematic approach of Lean to analyze their processes and implement improvements. It was very rewarding for me to watch the team present their findings and recommendations to their executive leadership.”

– Mike Loughrin, CEO, Transformance Advisors.

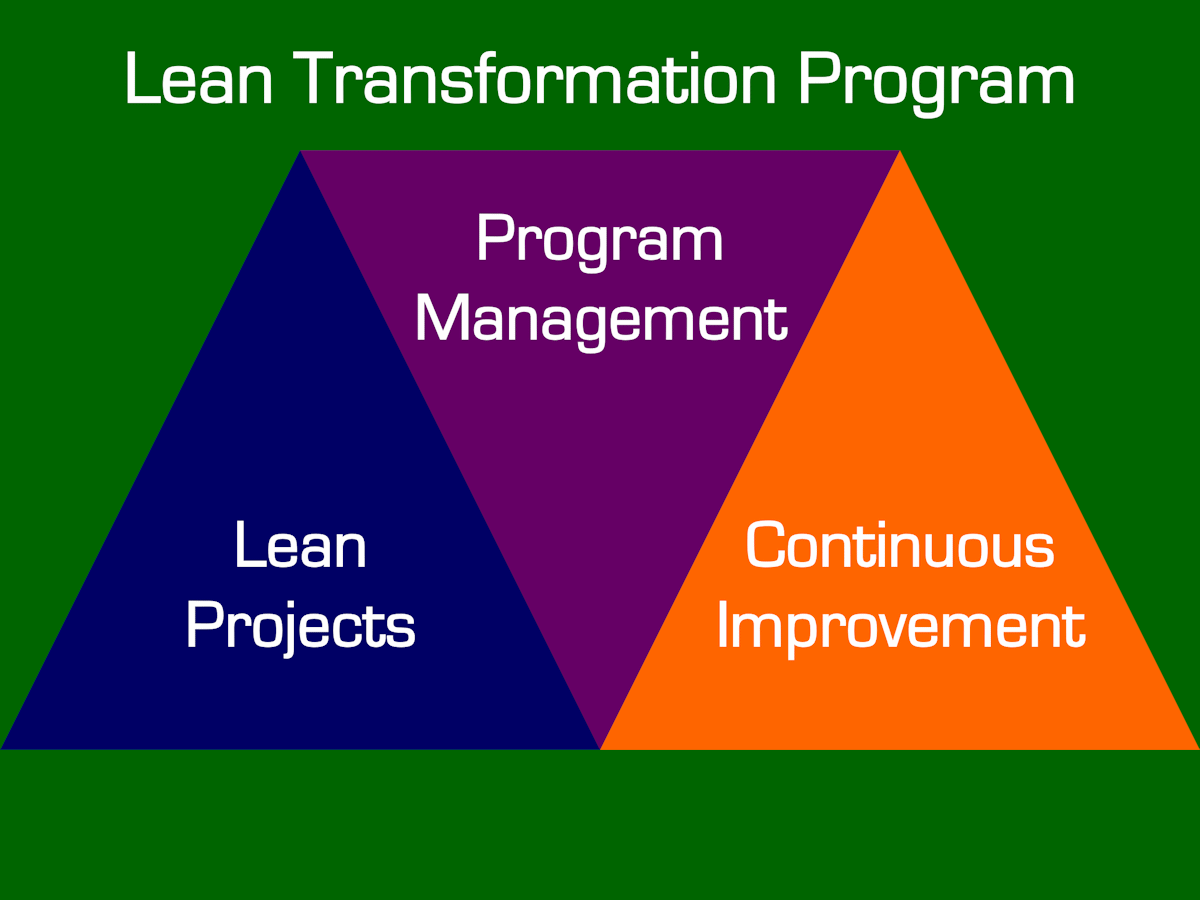

Lean Transformation Program

A Lean Transformation program is one of the best investments any organization can make. The return on investment (ROI) is better than many other strategic initiatives. Eliminating waste will improve customer satisfaction, increase revenue (or impact), and reduce costs.

The best Lean programs will contain three critical components:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

Learn more about the program, from Transformance Advisors, at: Lean Transformation Program.

Micro Motion Success

Wolf Robotics Success

Cartridge King Success

What is Lean Transformation?

Recognizing the Need for Lean

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors