Decreasing Lead Times & Increasing Revenue

Client

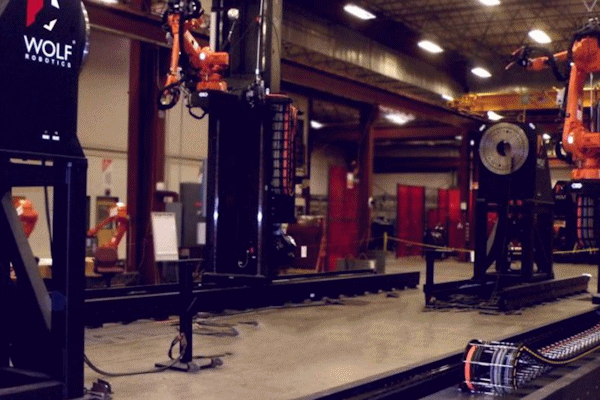

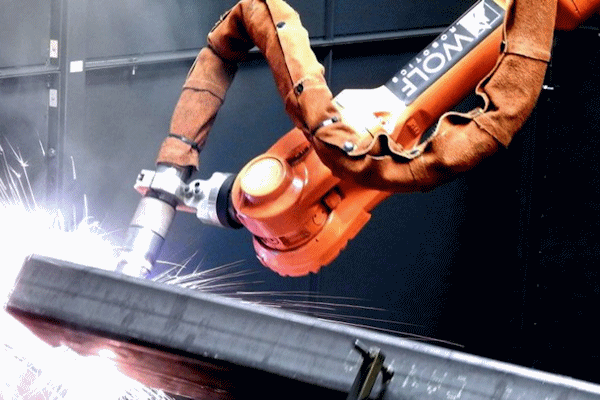

Wolf Robotics, located in Fort Collins, Colorado, specializes in solutions for metalworking automation with arch welding systems, cutting systems, material handling systems, and laser cladding systems to the mining, construction, agricultural, and energy industries. Founded in 2003, Wolf Robotics offers quality automation products and systems along with a wealth of experience, outstanding customer service, and a large support network.

“This is the most effective program and practical approach to driving competitive advantage I have seen in years!”

– Kent Sorenson, Senior Supply Specialist, Wolf Robotics

Challenge

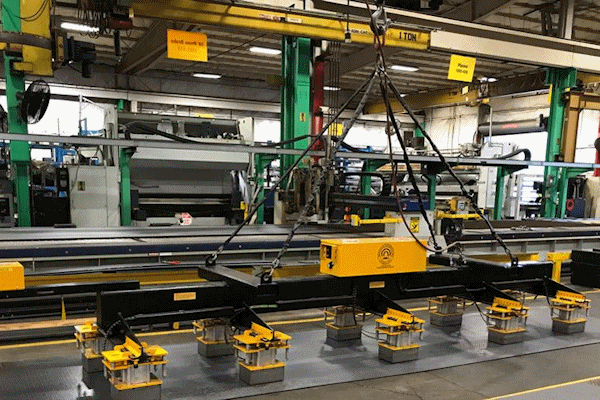

Wolf’s customers require cost effective automation solutions to help them create or improve their manufacturing processes. On time arrival is extremely important as the systems from Wolf need to be installed according to tight schedules that could involve a facility shutdown or coincide with the start-up of a new operation.

Dealing with lead times between 16 to 24 weeks for critical materials and components was making it very difficult to manage costs and meet on time arrival requirements. Maintaining a large inventory of raw materials and components might help with meeting customer orders, but that implies you could actually forecast what might be ordered in an environment where almost every customer requirement is unique. The alternative is to quote long leads that customers can’t live with and will cause them to order from the competition.

After trying both options – high inventory causing high carrying costs and long lead times causing lost business, the leadership team for Wolf was searching for a better alternative.

To find that better approach, the leadership team challenged Kent Sorenson to leverage Lean techniques to reduce customer lead times without having to make speculative and risky inventory investments.

Engagement

Kent Sorenson enrolled in the Certified Lean Master (CLM) program offered by Transformance Advisors. Through this course, Kent was provided knowledge in Lean techniques and coaching in the application of this knowledge while he ran a Lean project to address the lead times issues at Wolf.

Kent began by specifying customer value and creating a value stream map of Wolf’s current state. In doing so, he enabled his team at Wolf to see the waste in their value stream, with an emphasis on the impact of long lead times and excess inventory.

Using the current state value steam map, Kent and his team were able to identify the best opportunities to eliminate waste. An big opportunity involved working with suppliers to create a more collaborative relationship. This integration of Lean techniques with best practices in supply chain management is one of the competitive advantages of the CLM program.

Kent and his team were able to work with suppliers to create a future state map that showed how to create flow and leverage pull. It showed a means to have all components delivered to the point of use at the beginning of the final assembly process.

Results

Wolf’s Lean project took a value stream with lead times which ranged from 16 to 24 weeks and reduced them to 8 weeks. This reduction allowed purchasing to leverage pull by waiting for firm customer orders before they had to place orders with suppliers and also eliminate the need to carry $250,000 in speculative inventory.

The reduction in inventory is great, but the most rewarding benefit is how the improvements have allowed Wolf to quote shorter lead times and win more business. Very soon after the shorter lead times were used on customer quotes, the company gained $2,500,000 in business that would have, in the past, gone to the competition.

“Kent did an excellent job in leveraging the Certified Lean Master program to learn the details on the five principles of Lean and the systematic elimination of waste. He immediately applied this knowledge to his Lean project and included his suppliers in the improvement process. The team at Wolf Robotics is now in a great position to continue the cultural transformation required for crafting a sustainable organization.”

– Mike Loughrin, CEO, Transformance Advisors.

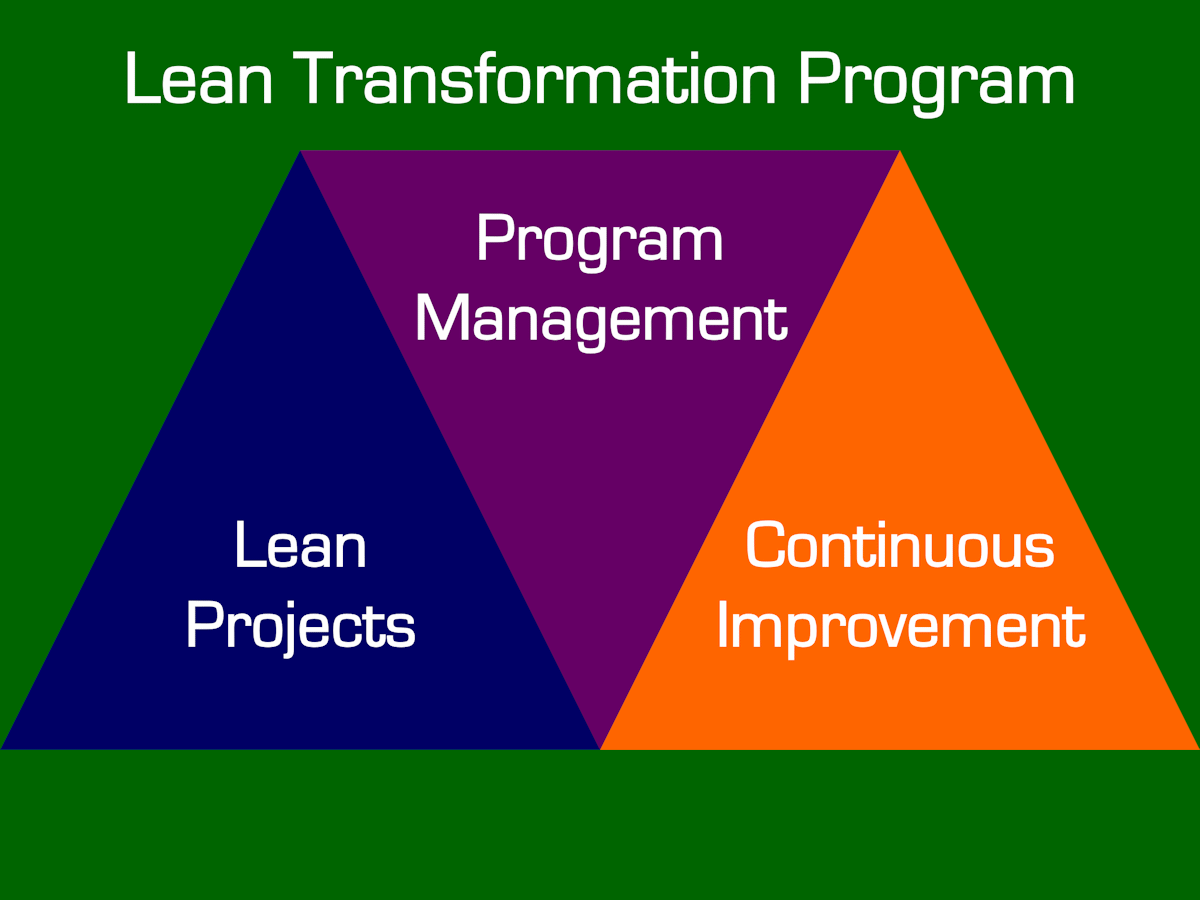

Lean Transformation Program

A Lean Transformation program is one of the best investments any organization can make. The return on investment (ROI) is better than many other strategic initiatives. Eliminating waste will improve customer satisfaction, increase revenue (or impact), and reduce costs.

The best Lean programs will contain three critical components:

- Lean Projects: Our research and experience has revealed the key to success is executing well-defined Lean projects. These projects must engage employees to eliminate waste and deliver significant improvements.

- Continuous Improvement: Lean projects will provide you better and stable processes. This is the time to leverage continuous improvement to keep getting better and respond to the constant change swirling around you.

- Program Management: Maintaining a portfolio of improvement projects, communicating the exciting accomplishments, dealing with change management, and providing educational events for everyone are just some of the requirements for a successful Lean Transformation. You need a champion focused on your Lean Transformation program.

Learn more about the program, from Transformance Advisors, at: Lean Transformation Program.

Talley Success

Micro Motion Success

Wolf Robotics Success 1

Recognizing the Need for Lean

What is High Flexibility Scheduling?

Subscribe to our newsletter

References

Organizational Improvement Acronyms by Transformance Advisors

Organizational Improvement Definitions by Transformance Advisors